Chemical Resistant Flooring in NZ

Built to withstand harsh substances, heavy machinery, and constant traffic, our coatings deliver long-term performance where durability matters most.

The Solid Floors Difference

Engineered Protection for Demanding Environments

Every chemical and abrasion resistant coating system is designed to match your specific operational conditions. From exposure to aggressive chemicals and oils to constant mechanical wear, our solutions are engineered to deliver reliable protection in demanding New Zealand workplaces.

End-to-End Expertise

From initial consultation and surface preparation through to application and handover, all work is completed by experienced in-house specialists. Our streamlined process minimises disruption, ensuring your facility remains operational while achieving a tough, seamless finish.

The Benefits of Chemical & Abrasion Resistant Coatings

Choosing chemical resistant flooring provides essential protection for environments exposed to harsh conditions, heavy wear, and strict safety requirements.

Superior Chemical Resistance

Chemical resistant coatings create a durable, non-porous barrier against acids, oils, solvents, fuels, and cleaning agents. This protection prevents staining, chemical penetration, and surface breakdown over time.

Exceptional Abrasion Resistance

Built for demanding environments, these coatings withstand constant foot traffic, forklift movement, and heavy machinery use. The surface maintains its integrity even under continuous mechanical stress.

Seamless & Hygienic Surface

The seamless finish eliminates joints and weak points where chemicals, moisture, or contaminants can accumulate. This helps maintain surface integrity while improving hygiene and cleanliness.

Structural Concrete Protection

By shielding the concrete substrate from chemical attack and abrasion, these coatings prevent cracking, erosion, and long-term structural damage. This preserves the strength and usability of the floor.

Reduced Maintenance & Repair Costs

Protective coatings minimise surface wear, reducing the frequency of repairs and resurfacing. This results in lower maintenance costs and a longer overall floor lifespan.

Improved Safety & Compliance

Slip-resistant textures can be incorporated to improve traction in wet or hazardous areas. This supports safer working conditions and helps meet workplace health and safety requirements.

Our Chemical & Abrasion Resistant Coating Systems

At Solid Floors, we deliver tailored protective coating systems using premium-grade materials selected for durability, safety, and long-term performance. Every system is designed to suit the specific conditions of your environment.

Chemical Resistant Epoxy Flooring

Chemical resistant epoxy flooring is one of the most effective solutions for protecting concrete surfaces in high-risk environments. Using high-performance epoxy coatings, we create tough, seamless floors that resist chemical attack and mechanical wear.

Epoxy coating systems offer:

- Excellent resistance to chemicals, oils, and solvents

- High abrasion and impact resistance

- Seamless, non-porous surfaces

- Long service life with minimal maintenance

Polyurethane Protective Coatings

Polyurethane coatings provide enhanced flexibility and resistance to temperature variation, making them suitable for environments exposed to thermal stress. These systems are commonly used where both chemical resistance and comfort underfoot are required.

Benefits include:

- Resistance to thermal shock

- Improved slip resistance options

- Enhanced durability in fluctuating conditions

- Long-term performance under constant use

Heavy-Duty Abrasion Resistant Systems

For areas exposed to extreme wear, we install high-build coating systems engineered specifically to handle constant abrasion. These systems are ideal for forklift traffic zones, loading bays, and production floors.

Features include:

- Increased coating thickness for added protection

- Exceptional resistance to mechanical wear

- Extended lifespan in high-impact areas

- Reduced surface breakdown over time

Protect Your Floors Today

Get durable, long-lasting chemical resistant flooring installed by Auckland’s experts. Contact Solid Floors now for a tailored solution that stands up to the toughest conditions.

Why Choose Solid Floors?

Choosing Solid Floors means partnering with specialists who understand the challenges of industrial and commercial flooring across New Zealand.

- Proven Industry Experience: With decades of experience, we have delivered chemical and abrasion resistant flooring solutions for a wide range of industries across Auckland and beyond.

- Tailored Coating Solutions: No two environments are the same. Each chemical resistant flooring system is specified to suit your operational risks, traffic levels, and compliance requirements.

- Premium Materials: We use trusted, industry-leading coating products designed for long-term performance in demanding environments.

- Minimal Operational Disruption: Our efficient installation process minimises downtime, allowing your business to continue operating while the work is completed.

- Long-Term Value: By extending the life of your concrete floors, our coatings help reduce repair costs and deliver excellent return on investment.

How We Install Chemical & Abrasion Resistant Coatings

Our proven installation process ensures every coating system delivers long-term protection, durability, and consistent performance.

Site Assessment & Consultation

We assess chemical exposure risks, traffic levels, and substrate condition to understand the specific challenges of your environment and determine the most suitable coating system.

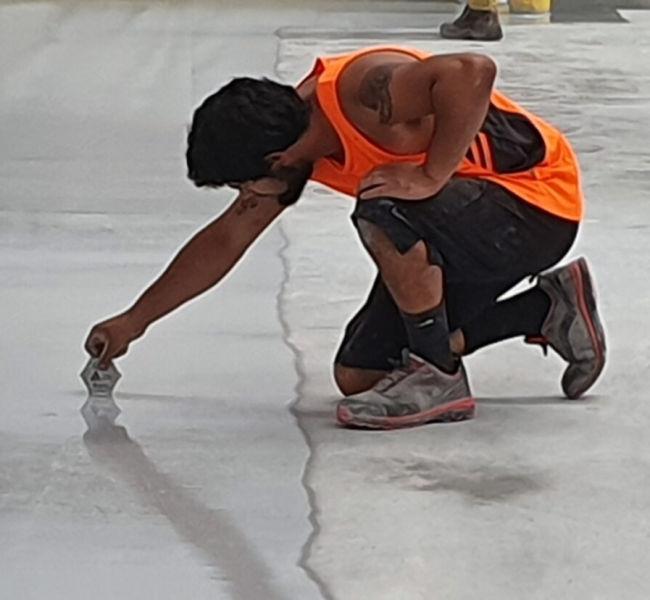

Surface Preparation

Precision grinding and preparation create a clean, stable base for coating application. Proper preparation is essential for strong adhesion and long-term coating performance.

System Selection

Based on your operational needs, we specify the most appropriate system, including chemical resistant epoxy flooring or polyurethane coatings, to ensure optimal protection and longevity.

Application & Handover

Our experienced technicians apply each layer with care to achieve a seamless, durable finish. The completed floor is inspected for quality and compliance before final handover.

Get Expert Chemical Resistant Flooring in NZ

Frequently Asked Questions

Chemical resistant flooring is specifically formulated to withstand aggressive substances such as acids, oils, solvents, and fuels. Unlike standard coatings, it provides a durable barrier that protects the concrete substrate from staining, corrosion, and long-term damage, making it ideal for industrial and commercial environments.

Yes, chemical resistant epoxy flooring is designed to endure heavy machinery, forklift traffic, and constant operational wear. When properly specified and installed, it maintains its integrity, ensuring a safe and durable surface in demanding industrial settings.

In most cases, yes. Existing concrete surfaces can be repaired and prepared to create a clean, stable base for the coating system, allowing for strong adhesion without the need for full slab replacement, saving time and cost.

With the correct system selection and proper maintenance, chemical resistant coatings can last many years. Even in high-traffic or chemically demanding environments, these floors maintain performance and appearance over the long term.

Yes, slip-resistant additives can be incorporated into the coating to improve traction. This enhances workplace safety and ensures compliance with health and safety regulations in wet, hazardous, or high-risk areas.

No specialised maintenance is needed. Routine cleaning with suitable products is sufficient to maintain both performance and appearance, making the floors easy to care for while extending their lifespan.

Costs are influenced by factors such as the condition of the substrate, level of chemical exposure, system type, coating thickness, and any safety or aesthetic requirements. A professional site assessment ensures accurate specification and pricing for each project.